Inside the World of a Plastic Bottle Factory and Its Production Process

From beverages to skincare, plastic bottles serve numerous purposes. Such flexibility in application, however, comes from a rather intricate manufacturing process that involves several stages including sourcing raw materials and packaging the final products. ZHENGHAO is a plastic bottle manufacturer that caters to clients from all over the globe with customizable solutions tailored to specific needs.

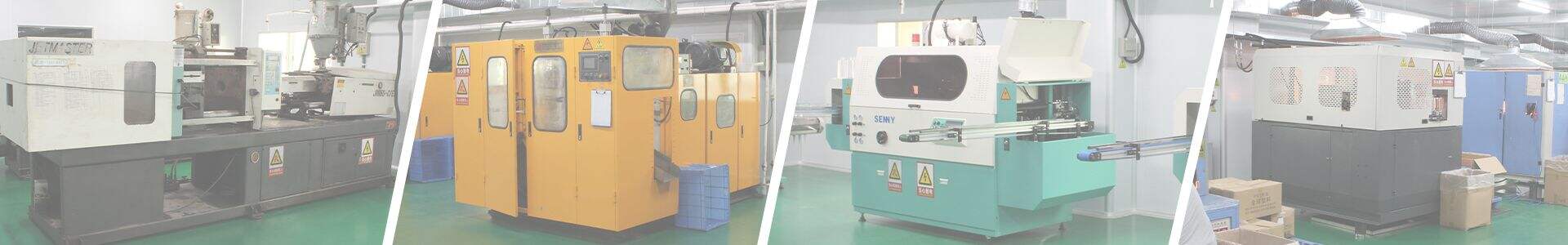

Methods of Manufacturing a Plastic Bottle

Standardized methods are typically employed for the manufacturing of plastic bottles to ensure the end products are consistent in quality:

Preparation of Raw Materials

Initial steps of the production processes include selection of lightweight and recyclable materials such as Polyethylene Terephthalate (PET).

Injection Molding

During the molding process, the initial substance is heated to a high temperature in order to make it liquid enough so that it can be injected into a predetermined mold. The mold cools, taking the shape of the object needed, in this case, a bottle.

Blow Molding

An advanced technique called blow molding is used to produce plastic bottles. During this process, a small tube made of heated plastic called a preform is put into a blow mold which then has air forced into it. The resulting expansion of the preform makes it take the shape of the mold.

Post-Processing

Once the bottles are shaped using molds, they go through post-processing which includes removing excess plastic, putting labels on the bottles, and attaching caps or pumps.

Quality Control

Inspections are critical when monitoring the strength, toughness, and visual appeal of a bottle, making sure each one fits the criteria needed, which absolutely determines the quality of the product.

The Importance of Customization in Plastic Bottle Manufacturing

Customization is critical during the manufacture of plastic bottles as it ensures practical solutions to define product specifications:

Design Flexibility

Customization takes into account the elegant and functional needs of a brand and enables different shapes and sizes of bottles to be created.

Selecting The Material

Food-grade PET is ideal for storage container while there are biodegradable options for eco friendly choices which means a wide selection of materials is available when deciding the use of the bottles.

Decoration and Color

The wonder of it all is that there is no limit to creativity, bottle graphics could include custom colors, gradient finks and even flocking the bottles for greater appeal.

Conclusion

The industry of plastic bottle production is a complicated but still an appealing area as it encompasses scientific and technological + artistic aspect of doing business. At ZHENGHAO, custom plastic bottles are made with craftsmanship that values both form and function to meet the client’s standards. With the world working towards more eco-friendly and creative ways of packaging, more and more plastic bottle manufacturers will emerge to deliver their solutions.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

UK

UK

VI

VI

ET

ET

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

MY

MY