Plastic Bottle Manufacturing Sustainably Innovating

To satisfy the demand for containers of beverages, household items and personal care products across the globe, there has to be plastic bottle factories. These factories now face pressure to shift towards sustainable ways and technologies owing the growing awareness on plastic pollution. This article will explore some strategies employed by current manufacturers of plastic bottles in order to reduce their environmental impact further, while at the same time satisfying customer needs for eco-friendly goods.

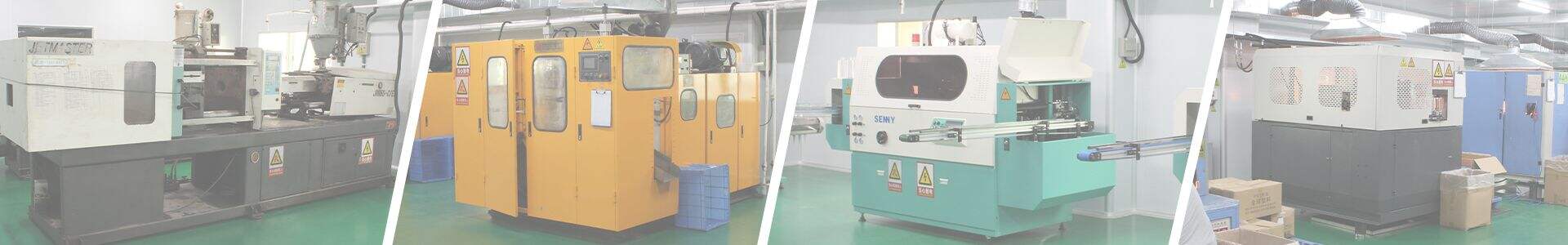

Efficient Production Processes

Sustainable manufacturing is anchored on efficiency. Modern-day plastic bottle plants are designed in such a way that they waste very little material, use less energy and release fewer amounts of carbon dioxide into the atmosphere. In addition, overall sustainability efforts get a boost from computerized systems as well as lean production concepts thereby allowing for maximum utilization of available resources.

Advanced Materials and Technologies

The sector is currently being transformed by groundbreaking materials. Various advancements including bio-based plastics from renewable sources or lightweight designs that retain their durability even though they use less material are reducing the environmental impact of these substances throughout their life cycles unlike before. Factories area also involved in many studies with an aim of making plastic recycling possible while ensuring that these bottles can decompose naturally as part of a circular economy.

Recycling Initiatives

Plastics disposal reduction begins with recycling. Closed-loop systems have linked up plants and bottling companies to make sure that old bottles go back through processing for remanufacture into new ones again. By so doing, it saves other resources but also reduces landfills and stops marine pollution as well. Furthermore, they have strengthened recycling infrastructure investments through collaborations with recycling partners.

Consumer & Regulatory Considerations

The desires consumers have and legal obligations expected in this sector sparks innovations in it.Customers’ taste for packages friendly to the environment is making them put their focus on sustainability when offering these products from different firms.Regulations that are environmentally stringent make sure good manufacturing practices knowing that there is trust among all stakeholders.

Conclusion

Plastic bottle factories are at a crossroads, balancing production demands with environmental stewardship. By embracing sustainable practices, adopting innovative technologies, and promoting recycling initiatives, these factories pave the way towards a more sustainable future. Together with consumers, regulators, and stakeholders, they can drive positive change and ensure that plastic bottles contribute to a circular economy that benefits both people and the planet.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

UK

UK

VI

VI

ET

ET

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

MY

MY