The part of Plastic Products Factories in the Today’s Manufacturing Landscape

Plastic Products Factories are extremely important for any manufacturing sector, as it produces a wide range of goods that are needed in different industries and daily life. They are the ones that make sure that there is coping up with the global demand for plastic products.

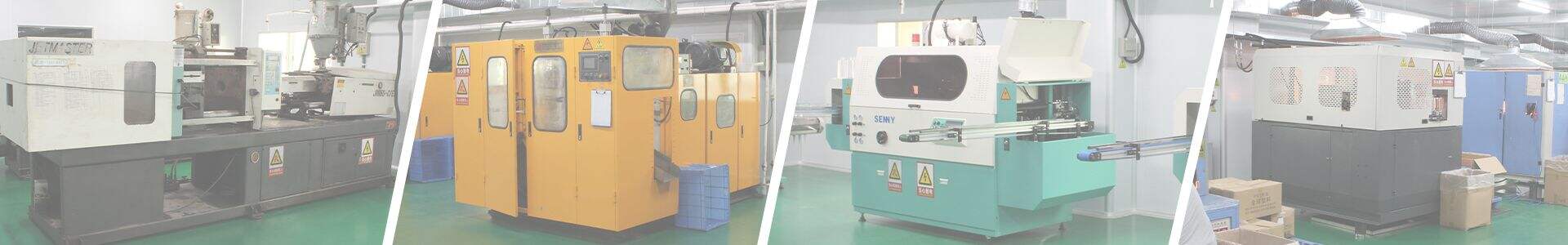

State-of-the-Art Manufacturing Processes

When making quality products with accuracy and speed, plastic products factories employ state-of-the-art manufacturing processes. Injection molding, extrusion, blow molding are some of them used to create various types of products; each designed to meet its requirement set in terms of size, shape and functionality.

Customization and Flexibility

Plastic products factories have been able to embrace customization and flexibility with regards to production as one of their key advantages. These facilities can incorporate individual design specifications by means of latest moulding technologies as well as adaptable materials so as to make tailor made commodities for numerous clients from multiple sectors.

Quality Control and Assurance

Stringent quality control measures must be maintained throughout plastic products manufacturing. Factories enforce strict quality assurance procedures during production stages to ensure that finished goods meet industry standards and comply with regulatory requirements. This dedication to excellence helps foster consumer trust while also instilling confidence among business owners.

Innovation and Sustainability

At the forefront of innovation are plastic product factories looking at better ways to enhance efficiency, reduce waste, lower environmental footprint amongst others. Eco-friendly materials or energy efficient methods of productions used at these sites lead to improved sustainability while meeting the growing demand for green products.

Supply Chain Management

To succeed plastic product factories require effective supply chain management. Such facilities work closely with raw material suppliers, logistics partners and distribution channels ensuring that there is a smooth flow from manufacturing to delivery. By streamlining their supply chains, plants can cut costs, shorten lead times, increase customer satisfaction levels etc.

In summary therefore; today’s plastics’products firms play essential roles through their employment of up-to-date methods in the production of a variety of goods that have customization, quality assurance, innovation and sustainability. As worldwide demand for plastic products continues to soar, these plants will serve as major sources of economic growth and offer invaluable solutions to many industries and consumers across the globe.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

UK

UK

VI

VI

ET

ET

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

GA

GA

CY

CY

IS

IS

MY

MY